A Bryant control should provide a wide range of machine vibration, from nearly motionless to full scale movement. If a control is operating as it should and was tested by varying the intensity of an incandescent (at least 40 watts or more) lamp load, then it should also vary the speed of a hopper, bowl or inline in the same way.

If turning the speed control knob doesn’t have the desired effect on your machine and you have confirmed the control is connected to a properly sized power source, there is something simple to check. On all Trigger boards, there is a small slide switch labeled with an “A” and “D” that needs to be configured correctly to obtain the best results.

Almost always, the “A” setting is for feeder bowls that are between 12″ and 36″ in diameter.

The “D” setting should be used for all hoppers, all inlines, bowls that are smaller than 12″ in diameter or bowls that are larger than 36″ in diameter.

To verify or change the A-D switch setting, simply remove the cover and slide the switch to the new position.

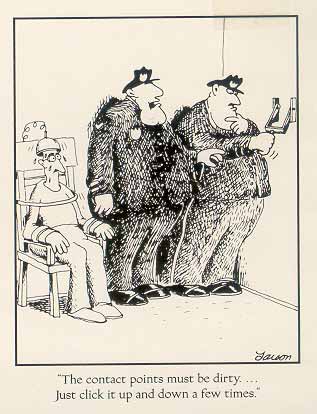

Note: Changing the A-D switch setting WILL make a noticeable difference in the operation of the system and will NOT cause any harm while evaluating the different settings. If changing the setting does not cause a noticeable difference, slide the switch back and forth a few times to clean the contacts.